Whether they gain the official rating or not, many strive to emulate the PassiveHaus building standard in either new build or renovation/extension projects – which is focused on an extremely airtight, fabric-first and highly energy-efficient design. Having such an airtight structure requires a high-quality ventilation system in order to create a healthy environment within your home.

Without a good ventilation system, your home can fall victim to a number of problems. Any moisture in the air can form condensation, encouraging the growth of mould and damage to the fabric of a building. Dust mites tend to flourish in damp conditions, and this can lead to an increase in dust-related allergies or asthma.

Things you might not even think of can remain in circulation throughout your home without a sufficient ventilation system; paint, cleaning products, and carpets can all release harmful organic compounds. On top of all this, there are also everyday odours from cooking, toilets, tobacco, and pets floating around the home.

EXTRACT ONLY VENTILATION OPTIONS

Background Ventilators and Intermittent Extractor Fans – This approach in the newest Building Regulations is now defined as Natural Ventilation and is only suitable for less airtight properties (higher than 5/(h.m2) at 50pa). A fan is required in all wet rooms, and background ventilators (trickle vents are) required in every room. For anyone who is striving for airtightness and energy efficiency, this ventilation approach is not applicable.

Continuous Mechanical Extract Ventilation (MEV/dMEV) – This approach works with either a central extract unit (MEV) or individual fans (dMEV) running continuously and is deemed suitable for all dwellings regardless of air tightness. Scottish Regulations state that this option should not be used on air permeability lower than 3/(h.m2) at 50pa, England & Wales Regulations also allude to possible unsuitability in highly airtight properties. Background ventilators (trickle vents) are required in all habitable rooms with this option.

Whilst extract-only ventilation will remove contaminated air from wet rooms, they also promote heat loss. The big weakness with extract-only options is that they require background ventilators (trickle vents) for air replacement. This air is drawn in at outside temperatures and humidity and can cause drafts as it is largely uncontrolled. Effectiveness depends on external factors like wind, and vents can get obstructed, affecting airflow, which can lead to poor air quality and impact building materials’ long-term integrity due to moisture and odours spreading throughout the home.

If you are building a low-energy home, it is crucial to ensure that it will be as airtight as possible. If you have an airtight house, extract-only strategies won’t be the right option. For this reason, most self-builders and those doing fabric-first renovations/extensions will incorporate Mechanical Ventilation with Heat Recovery into their projects.

MECHANICAL VENTILATION WITH HEAT RECOVERY SYSTEM (MVHR)

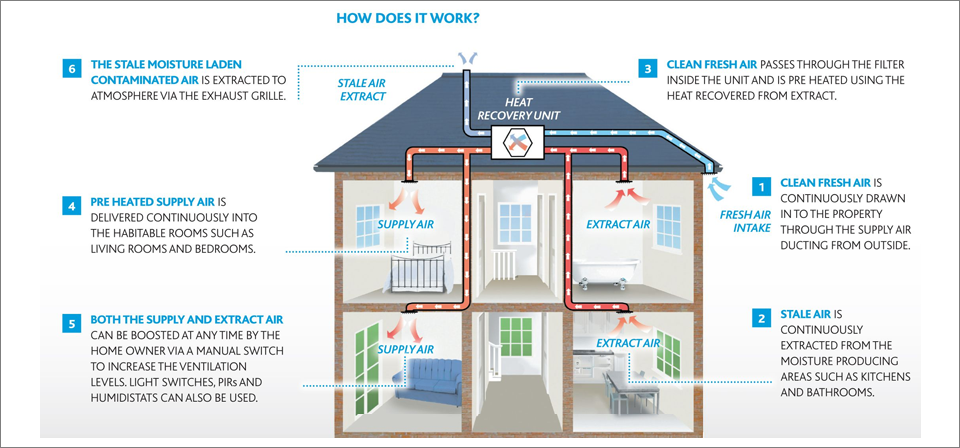

An alternative ventilation system to the ones mentioned above is Mechanical Ventilation with Heat Recovery System – or MVHR. This system provides an ideal ventilation solution. The technology couldn’t be more straightforward. Stale air is taken away from ‘wet’ rooms in the home through a combination of hidden ducts. This air passes through a heat exchanger in the unit of the main system, which is installed discreetly in an attic, plant room or cupboard. UK-based experts, ADM Systems, explain that the MVHR system works much in the same way our own bodies work:

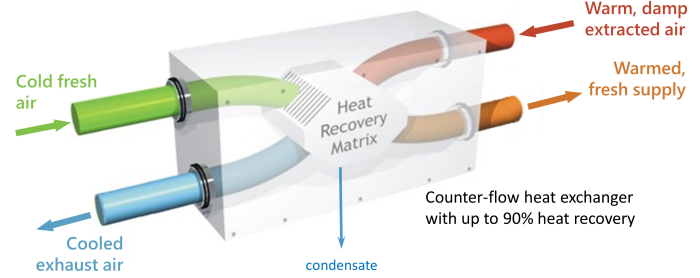

The stale air is taken through the ducts from the ‘wet rooms’ in the house, such as kitchens and bathrooms. This air then passes through to the ventilation unit and over the heat exchanger – which can recover as much as 90% of the heat in this air that would typically be lost in traditional means of ventilation. At the same time, fresh air is continuously brought in from the atmosphere, filtered to remove the likes of pollen, carbon, and insects before it passes over the heat exchanger and ducts through the rest of the house – providing a balanced ventilation system and clean air.

MVHR systems have efficiencies in excess of 90%. Typically, supply air through the system will only be 1-1.5 degrees cooler than extracted air, so it will complement all types of heating systems by considerably reducing their demand without compromising the comfort levels of occupants.

The heat recovery products can help to reduce a building’s carbon emissions by reclaiming and redistributing the heat into the property which would have been wasted if a extract-only system had been used instead. Unlike extract-only systems, such as trickle vents or extractor fans, no thermal bridging occurs from using an MVHR system. The energy saved using the MVHR contributes to a reduced Dwelling Emission Rate (DER) in the Standard Assessment Procedure (SAP).

MVHR systems also offer huge benefits towards achieving building standards. Heat recovery uses just a few Watts of energy (<1W/l/s) to recover many kiloWatts of otherwise wasted heat from conventional ventilation systems. This results in lower energy bills and carbon emissions.

ADM Systems point out that, in modern buildings, 35% of heat loss can be attributed to ventilation and air leakage. MVHR will considerably reduce this heat loss – confirming its status as a practical and energy-efficient ventilation solution.

PURGE VENTILATION/OVER HEATING

It’s worth mentioning the role of purge as part of a ventilation strategy. The main purpose of an MVHR system is to provide the background ventilation for a property with occasional boosting for quicker clearing of moisture when bathrooms etc. are in use. However, there will be times when there will be a need to increase airflow to relieve heat build-up/stuffiness.

Overheating has become a bit of an issue in airtight houses, so much so that there are now documents in Building Regulations north and south of the border to advise on this subject. Purge ventilation will help by opening doors/windows for short periods, e.g. morning and evenings to cool a building down and is actively encouraged even in Passive Houses. MVHR systems can also contribute at certain times of the year by adjusting settings to activate a summer bypass.

The key to minimising overheating is to design out the heat with energy-efficient design, orientation, fenestration, and shading. We recommend you talk to your architect at the early design stage to look at the best way to apply these measures to mitigate overheating.

Brian Singleton of ADM Systems answered some of our key questions Self Builders might have about MVHR systems:

By kind permission of Total Home Environment

WHAT IS THE AVERAGE UNIT COST FOR A 4-BEDROOM FAMILY HOME?

There are many MVHR units on the market, currently over 200 in SAP Appendix Q and over 70 Passive House Accredited. Some units come with basic features through to more sophisticated, integrated controls. The range of system prices for a typical 4-bed Self Build would be from £5,000 to £6,000 (supply only), depending on the specification and size of the property. The running costs for a properly designed and installed system would be in the region of £60 to £80 annually.

WHAT MAINTENANCE DO MVHR SYSTEMS REQUIRE?

The main maintenance is the cleaning and changing of filters twice a year. Most can be cleaned and used again before replacing. The filter costs vary from £30 to £60 depending on the manufacturer and size of the unit. The heat exchanger would also need inspection every 2/3 years or so. It is removable and washable, and all maintenance on MVHR systems is something that can be done by the homeowner.

CAN SELF BUILDERS INTALL THE MVHR SYSTEM THEMSELVES AND GET YOU TO COMMISSION THEM?

Very much so. Most of our projects are self-install, either by clients themselves or one of their trades. We provide them with schematic layouts and installation instructions and technical support, and site visits. The radial semi-rigid duct system is very attractive for Self-Builders as it is easier, quicker, and more of a fail-safe ducting system for self-install.

WHO ARE THE MARKET LEADERS IN THE INDUSTRY AT THE MOMENT?

There are two distinct markets for MVHR. First, there are the multi-application projects such as social housing, or apartment developments. These projects are very price-driven and manufacturer-led by companies such as VentAxia and Greenwood AirVac.

Then, there is the Self Build market. Currently, there are around 15,000 Self Builds per annum – representing approximately 12% of the total new homes built in the UK. Manufacturers are active in the Self Build market. However, this is not their core business – so companies such as ADM Systems offer bespoke solutions and are better suited to the contemporary house designs seen in the Self Build market.

WHAT SEPARATES ADM SYSTEMS FROM THE COMPETITION?

ADM are an independent company dealing with many manufacturers, so we can offer choice to suit the project. We have been in the marketplace since the early 90s and have a wealth of experience. ADM Systems are not just suppliers of Heat Recovery Ventilation – we offer a full range of ‘buddy’ services for Self Builders installing their own heat recovery systems.

We also offer Compliance advice, complete installation by BPEC/NIC-EIC -approved engineers, commissioning and balancing and full ventilation system maintenance and aftercare packages. We also offer ground-to-air heat exchangers, air-tempering active cooling to enhance MVHR systems and central vacuum systems.

WHAT WOULD BE YOUR TOP TIPS FOR NEW SELF BUILDERS?

Step 1: Think ‘Fabric First’ – consider a thermal strategy early and strive for airtightness from your Self Build

Step 2: Determine the level of heat required for your Self Build.

Step 3: You must consider how to ventilate – ventilation can represent a huge percentage of the heat loss in a building, and this can have an impact on the first two steps. Think carefully about your system’s location – you may find planning regulations can dictate that certain conditions are met.

Controlled ventilation = Controlled heat loss (MVHR), whereas Uncontrolled Ventilation (Extract Only)= Uncontrolled Heat Loss.

‘Build Airtight, Ventilate Right’ – remember this, and you should be on course for an energy-efficient Self Build that will be comfortable and inexpensive to run.

WHAT STAGE WOULD YOU (ADM SYSTEMS) NEED TO GET INVOLVED IN A SELF BUILD PROJECT LOOKING TO UTILISE AN MVHR SYSTEM?

As early as possible. Initial sizing/costings can be done from any architectural or planning drawings. Once the construction method has been finalised, if appointed, we proceed to the MVHR design stage. We would liaise with the client, architect, kit supplier and structural engineers as necessary.

This liaison and cooperation help to integrate the system into the structure smoothly whilst maintaining the aesthetics of the internal finish.

HOW LOUD IS THE MVHR SYSTEM?

The key to minimising noise is to ensure that your MVHR system is sized correctly for your property. If a system is undersized or value engineered to suit a budget, then units would have to work too hard to achieve regulation airflows and potentially would be noisy. Location of the unit, positions of supply and extract points in rooms and quality of installation are all factors. All systems should also incorporate silencers to prevent air noise from travelling down ducts.

An MVHR system that follows these good practice principles will ensure that systems run quietly in the background and are not intrusive to occupants.

ADM are seeing a big increase in renovation/extension projects driven by spiralling energy costs. Clients are realising that the fabric first, insulation and airtightness principles can be applied to these types of projects.

Our advice in any existing home or renovation/extension project is to improve insulation and airtightness as much as you can. Then, MVHR is a possibility. Clearly, in this type of project, the installation may need careful consideration, so as with new builds, take advice and engage early as to the viability of installing a system.

Our special thanks go to Brian Singleton and ADM Systems for their help and contribution to this blog. Along with ACA, Brian offers his expert advice at Self Build Seminars – hosted by ACA in our Scotland and England offices throughout the year. For more information or to sign up for the next seminar, click here.